ISO 9001 and VDA 6.2 certified

Highest Quality Demands

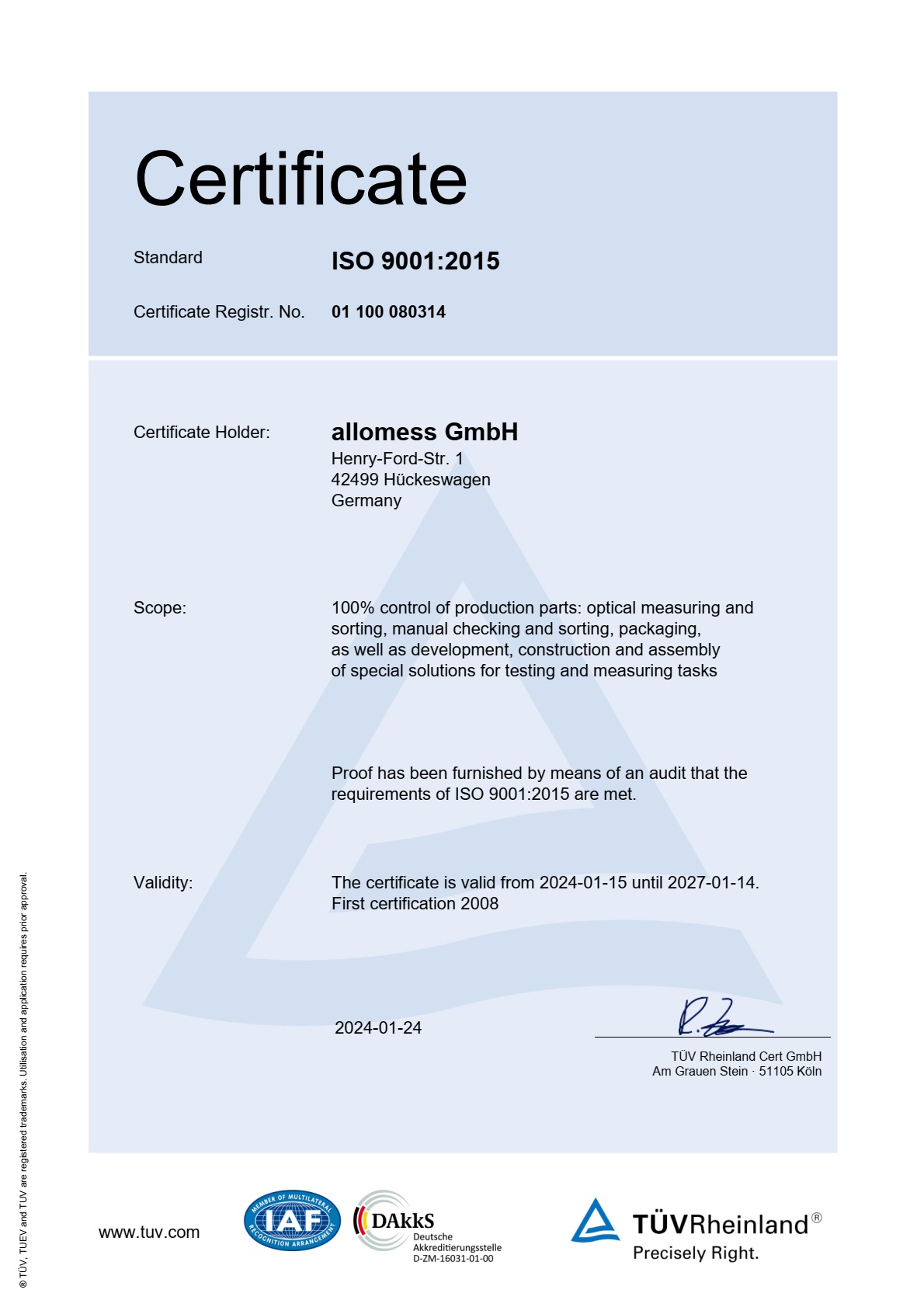

The complex requirements in metrology demand an enormous amount of expertise and knowledge. We will find the ideal solution for your task by using the most modern measuring equipment. We operate an elaborate and consistent quality management system throughout. We maintain the quality of our processes and service at the highest level and constantly strive to improve them. We are certified according to ISO 9001 and since the beginning of 2018 also according to VDA 6.2.

Based on IATF 16949, certification according to VDA 6.2 is aimed at service providers of german automotive manufacturers and contract testers of automotive parts. The objectives of VDA 6.2 are continuous improvement of the corporate strategy, the company's value chain and customer satisfaction.

ISO 9001:2015

VDA 6.2:2017

PDF download by clicking on the certificates

Our Passion for Perfection

Contract Measuring in 100% Quality

Conscientiousness meets Contract Measurement Technology

If the production result consists exclusively of good parts, the common goal has been achieved. However, in contract measurement technology, the path to this goal is a great challenge for everyone involved. We do our part with 100% conscientiousness by selecting only qualified staff. With us, you will only find competent professionals who strive to adapt processes to your wishes and act as problem solvers. We will answer every question about services in the field of contract measurement and contract sorting immediately. We react and decide quickly. For us as a contract measurement service provider, meeting deadlines, including special deadlines and rush requests, is just as much part of our quality promise as 100% product quality.

Precise and Reliable

Our 40 employees are experts in all fields: from development, construction and services in contract measurement technology. This is what we stand for 24 hours a day, 360 days a year. The standards and requirements of the automotive industry are considered the most demanding within the manufacturing sector. We fulfil them as a contract measurement service provider. This knowledge and expertise is transferable to other industry sectors for the benefit of our customers. The high quality of work performance in testing and sorting and the associated 100% quality control contribute to defect-free products. Through continuous improvement of all adjusting screws, 5μ reproducibility can be realised even at 400 parts per minute. Upon completion of the measuring process, the test parts are precisely packed and labelled. Our own truck can deliver your products upon request. Having our own shipping option saves us time and allows us to be more flexible to your demands.

Reliable Contract Measurement Technology thanks to SAP

Contract measurement technology of the highest quality also means maximum security. We schedule exclusively with SAP. You will receive a certificate for every test job. The use of state-of-the-art IT technology ensures a high level of process and data security. We have also taken precautions with the installation of UPS (uninterruptible power supply) to bridge power failures. We are able to guarantee the availability of our testing facilities.